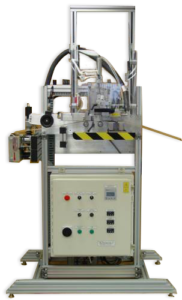

Core Gluing System

Spraymation has been promoting the use of a Slot Coater Applicator Head to extrude a thin film of cold adhesive onto the webs used for 2 ply spiral wound cores, eliminating typical “pot and roller” equipment. A number of users have now implemented this new technique. The Spraymation direct core glue application equipment, now in its third generation, is in operation 24/7, at numerous sites.

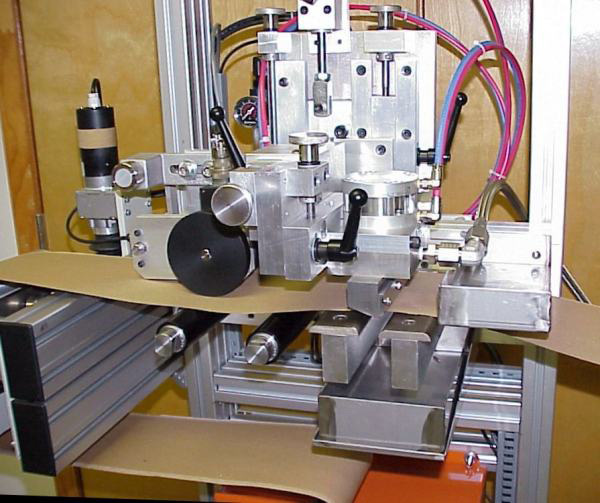

The Core Gluing System includes web supports which allow uniform coating at low web tension, and an active electronic servo-controlled Web Guide System, providing +/-.005” (+/-.13mm) control. The Applicator Head mounting system has four independent adjustments to obtain the optimum adhesive coating. The included Metering Pump Module, delivering precise amounts of adhesive, is a gear pump driven by an electric motor.

Special equipment is available for applications requiring the dispensing of heated adhesive, or for use with central adhesive distribution systems. In some instances, standard Test Stand Equipment is available for “trial and evaluation” purposes.