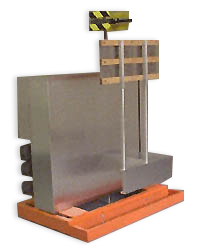

Automatic Test Panel

Standard 310940

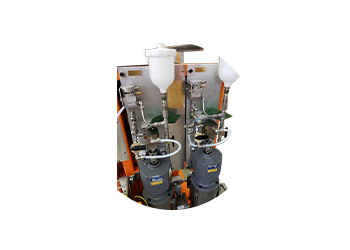

Automatic Test Panel Spray Machine models are available from highly sophisticated custom units to a variety of standard models with various speed ranges and panel spray areas.

With all models, the operator can select all spray parameters including gun traverse speeds, panel indexing distance, spray on distance, and all other variables. Once the program is complete you may start the spraying sequence or assign a program number and place the information in the on-board computer memory for future recall.

The 310940 Series Machines are new in design and function from the ground up. The index mechanism is relocated to the left and near the front of the unit, away from the paint overspray area. Periodic maintenance and lubrication of the index mechanical components are reduced significantly. The new frame design allows easier access to place and remove panels.

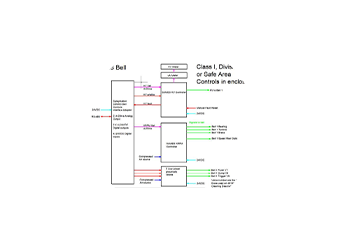

- Standard power requirements are 120 VAC, 50-60 hertz, single phase.

- A two line, 24 character per line LCD display, a single data input knob and a few push buttons are the operator interface. The machine is controlled by functions and data from various menu selections. Many new functions have been added.

- Memory Function – The machine will store 99 separate scripts for instant recall. Scripts are assigned an eight character (A to Z or 0 – 9) name when placed in memory.

- Complete diagnostic functions are incorporated. These functions are used to identify and/or isolate defective components. Information will be displayed about each test as it is performed. The test functions can be initiated by the operator or technician. The tests can be completed in the operating environment without opening the control enclosure.

- Two (2) years parts warranty.

- “Gun On” spray distance is selected from the control panel.

- Spray direction may be selected left to right, right to left, or bi-directional.

- “Gun On Before” and “Gun On After” times are added to allow the spray gun to be activated for a time before and after the programmed painting has been reached to allow full pattern development.

- Vertical index start position has been added to automatically position the test panels at a desired height for the first painting stroke.

- Strokes per coat may be selected from the control panel. This will allow choosing the number of strokes required to cover the particular panel size used. Paint will be saved and clean-up reduced.

- Three separate flash times may be selected, flash time between all spray coats applied from Gun 1, flash time on the change from Gun 1 to Gun2, and flash time between all the spray coats from Gun 2.

- Wedge coating film build programs. Coating applied, progressing from a heavier film build to a lighter film build may be selected to progress from top to bottom or bottom to top. This will allow hiding, sag and other tests to be observed on a single panel.

- Test functions consist of three main menu entries, traverse speed, vertical index, and spray guns.